METALPHOTO

TRUSTED WHERE PERMANENT IDENTIFICATION IS CRITICAL.

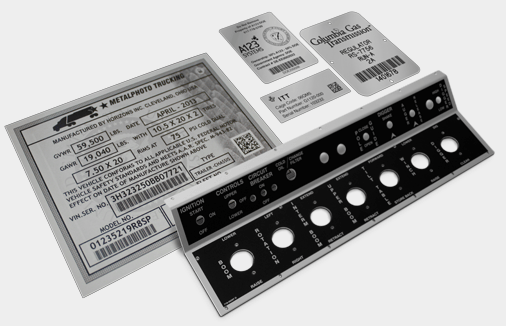

For over 50 years, industrial and military engineers have specified Metalphoto photosensitive anodized aluminum for durable nameplates, barcode labels, service schematics and control panels installed in harsh operating environments. Metalphoto’s proprietary technology permanently seals a UV-stable image inside of anodized aluminum, offering the confidence of unparalleled durability, image resolution and readability. Click here to compare to other materials.

How We Work?

Exceptionally Durable

Metalphoto® photosensitive anodized aluminum combines extreme durability in harsh environments with a high-quality, long-lasting appearance. These nameplates and labels function perfectly for years, maintaining their original appearance under many challenging conditions including extreme heat, humidity, long term exposure to weather, UV and other outdoor conditions, salt spray, abrasion, industrial solvents and chemicals. In outdoor uses, Metalphoto® has a 20 year guarantee. Guarantee is for gold, silver and black color only, other colors can last up to 5 years. Note that gold and silver cannot exist on the same part. The entire piece is dipped, which is what gives it the gold color, and cannot remain silver. Metalphoto® lasts a lifetime indoors.

An ideal material selection for production requirements ranging from small to high volume

Metalphoto® makes an excellent material choice for short and medium run production requirements or when a large volume of unique or one-of-a-kind parts are required. Panels, nameplates and labels may be produced quickly and economically.

Metalphoto® Services

Finishes :

- Silver Satin: Semi-gloss; Medium Reflectance; Grain Direction Light but Apparent (Mill Finish Grain); Widely Specified for Nameplate, Signage and Equipment Panel Applications.

- Silver Matte: Non-Reflective; Recommended for Linear and 2D Data Matrix Bar Code Labels and Applications Requiring a Non-Glare Surface.

- Silver Gloss: Highly Reflective: Mirror-Like Appearance. Limited to 0.020″ thickness.

- Full Color: It maintains color vibrancy and clarity even when exposed to UV radiation, abrasion, chemicals, and extreme temperatures.

Applications:

- Nameplates

- Panel Fronts

- Variable Information Plates, Linear and 2D Data Matrix Bar Code Labels

- UID Labels

- Data Plates

- Indoor and Outdoor Signage

- Wiring Diagrams & Schematics

- Plaques & Awards

Fastening options:

- Adhesives

- Mechanical: Rivets , Screw or Hang

Applications:

- Outdoor: 20 years with gold, silver or black. Up to 5 years in other colors.

- Indoor: Will last longer indoors since it is not exposed to harsh environments and UV light.

Sizes:

- 10″ x 12″, 12″ x 20, 20″ x 24″. Spec or custom size sheets also available.

Performance Characteristics:

- Extremely Durable; Resistant to Chemicals, Abrasion, High Heat, UV, Outdoor Weathering.

Thickness:

- .003″, .005″, .008″, .012″, .020″,.032″, .063″

Material:

- Photosensitive Anodized Aluminum Sheets.

WHEN TO USE METALPHOTO?

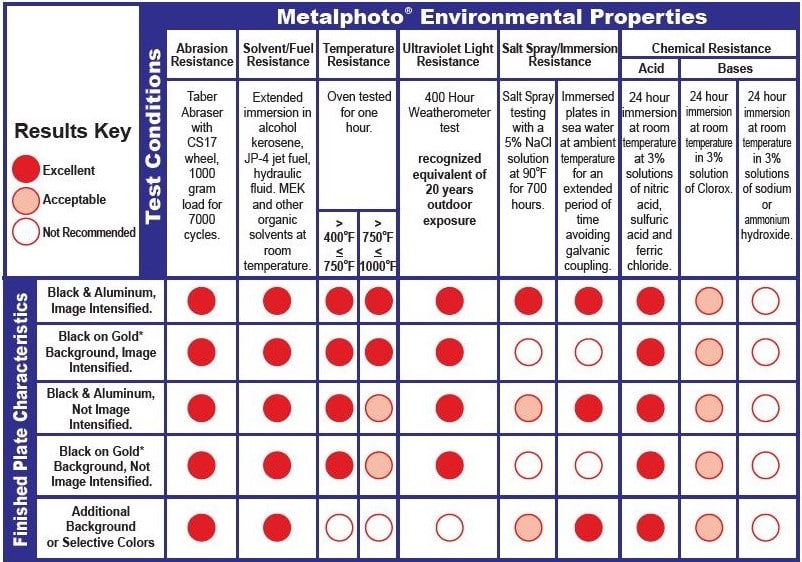

Because Metalphoto is resistant to many conditions commonly found in outdoor environments that would erode most identification products printed on other materials, Metalphoto is the perfect material for any nameplates, signs, labels or control panels that need to stand up to harsh outdoor environments, or any project where permanent identification that will remain legible for the life of the product is crucial. See Metalphoto’s durability characteristics below:

Weather/UV Resistance

TESTING

A 400 hour Weatherometer Test GG-P-455P, which is the estimated equivalent to 20 years of outdoor exposure, had no affect on Metalphoto.

Abrasion Resistance

TESTING

7000 cycles on a Taber Abraser with a CS17 wheel, a total of 1000 gm. load, only resulted in a slight dulling of Metalphoto’s surface; the image was not affected.

Temperature Resistance

TESTING

Standard Metalphoto readable up to 500°F, Image Intensified Metalphoto readable up to 800°F. Both tested for a 24-hour oven exposure. Inquire for heat resistance up to 1,000°F.

Corrosion Resistance

TESTING

Exposure to 5% salt spray as 95°F for 700 hours had no effect on Metalphoto.

Corrosion Resistance

TESTING

Metalphoto was immersed in a full battery of chemicals at different temperatures for different lengths of time, all with little to no effect.